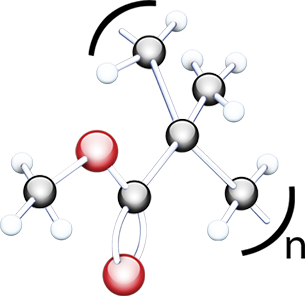

Acrylate: The building block of Hapla technology

The Hapla adhesive system represents both quality and safety and is based on over 35 years of scientific and clinical research and development.

Each Hapla product has been carefully designed to provide the level of performance needed to meet clinical requirements.

Hapla adhesive has been screened for safe use on human skin and is classified as having low skin irritancy. It is breathable with high rates of moisture vapour permeability.

All Hapla products have a long history of safe and effective use within clinical environments.

Major investment in our coating facility has ensured that operating under controlled clean conditions we have the versatility to apply Hapla adhesive to a variety of materials.

Hapla adhesive is applied in measured quantities, each scientifically calculated and varied according to material type and appropriate to its particular construction, thickness and intended use.

During the coating process the Hapla adhesive is energised, achieving chemical cross-linking and bonding the Hapla polymers to the fibres of the material to ensure optimum levels of adhesion and eliminate the possibility of delamination often encountered with other methods of adhesive application.

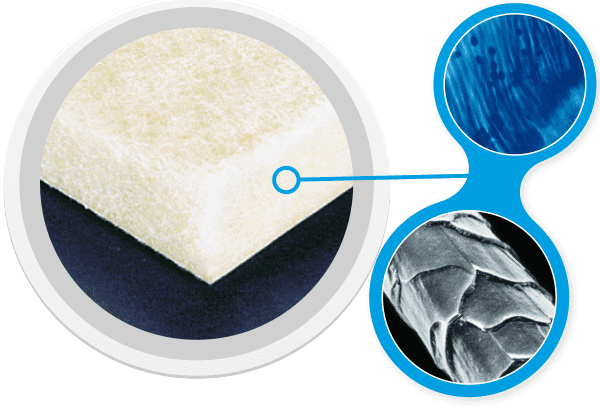

Images are property and copyright of csiro.

Wool follicles under the microscope, photographer – Livestock Industries.

Quality

Our manufacturing facility at Broadwell Road was purpose built in 1994 to meet the requirements for the manufacture of licensed pharmaceutical products.

As well as these medicinal products we manufacture medical devices, cosmetics and personal protective equipment under the same controlled clean conditions.

The site has a Pharmaceutical Manufacturer’s Licence, Wholesale Dealer’s Licence and we are accredited to ISO 13485. As a consequence our operation is subject to inspection and is audited and approved on a regular basis by both the Medicines and Healthcare Products Regulatory Agency and a Notified Body.